Transforming Sales Forecasting for an Auto Component Manufacturer with ERPNext

For an auto component manufacturer relying on Oracle ERP, monthly sales forecasting was stuck in Excel — manual, error-prone, and disconnected from actual production data. With limited room to customi

Client Overview

Our client, a prominent auto component manufacturing company, has been using Oracle ERP as its core system. However, due to the limitations of Oracle's legacy architecture, the development of new business-specific modules was proving to be both time-consuming and expensive. One such pain point was their Monthly Sales Forecasting and Monitoring, which was entirely maintained in Excel sheets — isolated, error-prone, and difficult to track in real-time.

To solve this, we designed and implemented a Monthly Sales Forecast Planning & Monitoring Tool using the Frappe and ERPNext Framework, which seamlessly interfaces with their existing Oracle ERP.

Challenges with the Legacy Process

- Manual Excel-based Forecasting:

- Forecast data was manually prepared, shared, and consolidated via email.

- There was no single source of truth, leading to data inconsistencies and errors.

- No Real-time Visibility:

- Stakeholders couldn’t monitor planned vs. actual production during the month.

- Updates and adjustments to forecasts were delayed or missed.

- Siloed Data:

- Production, Sales, and Planning teams worked in silos.

- Lack of integration between forecasting data and Oracle ERP limited end-to-end visibility.

- High Administrative Overhead:

- Consolidating forecasts from different business units was tedious and time-consuming.

- Misalignment often led to production inefficiencies.

The Solution: ERPNext-based Sales Forecasting Tool

We developed a custom application on ERPNext that automates and streamlines the forecasting process, tightly integrated with their existing Oracle ERP system.

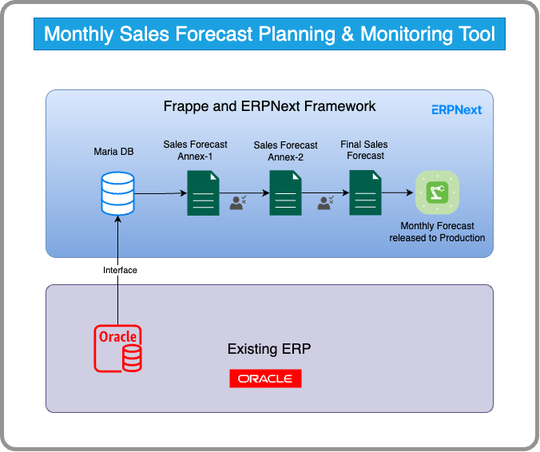

System Architecture

As shown in the diagram:

- MariaDB acts as the operational database for the new ERPNext module.

- Data is fetched from Oracle ERP via a secure interface and ingested into ERPNext.

- The forecasting process is divided into 3 stages:

- Sales Forecast Annex-1 (Regional / Departmental input)

- Sales Forecast Annex-2 (Review & Consolidation)

- Final Sales Forecast (Management Approval)

- Once finalised, the Monthly Forecast is released to Production, enabling a live comparison of planned vs. actual figures.

Key Benefits

1. Streamlined Workflow

The structured multi-stage process replaces the ad-hoc Excel workflow, ensuring accountability and proper version control.

2. Real-time Monitoring

Stakeholders now have access to dashboards that show planned vs. actual production data, enabling proactive course correction.

3. Better Collaboration

Sales, Production, and Management teams collaborate within the same system, eliminating redundant data entry and delays.

4. Scalable and Configurable

Built on the open-source ERPNext framework, the solution is highly customizable and can evolve with future business needs.

5. Cost-effective Integration

Instead of customising Oracle ERP, we offloaded the logic and workflows to ERPNext, interfaced cleanly with Oracle — saving cost and time.

Recommendations for Other Manufacturers

- If you’re using a legacy ERP like Oracle or SAP, and find it challenging to implement new business-specific workflows, consider integrating lightweight, modular systems like ERPNext for satellite functionality.

- Avoid relying on Excel for mission-critical processes like forecasting, especially when real-time data is key to decision-making.

- Think in terms of ecosystem architecture, where Oracle remains the core transactional system, and specialized tools like ERPNext handle planning, analytics, and collaboration.

Conclusion

With our ERPNext-based Monthly Sales Forecast & Monitoring tool, the client now experiences enhanced visibility, better coordination, and improved production planning. This project is a testament to how flexible, open-source ERP tools like ERPNext can fill crucial gaps left by traditional systems — and deliver tremendous value.

If you’re facing similar challenges in your manufacturing operations, let’s explore how we can help.

Satish Aralkar

Satish Aralkar (Founder – Vedarth Solutions) is SAP consultant having 15 years of SAP implementation and 12 years of Domain experience in manufacturing domain. Currently working on ERPNext implementations, Automation and Digital Transformation.

No comments yet. Login to start a new discussion Start a new discussion